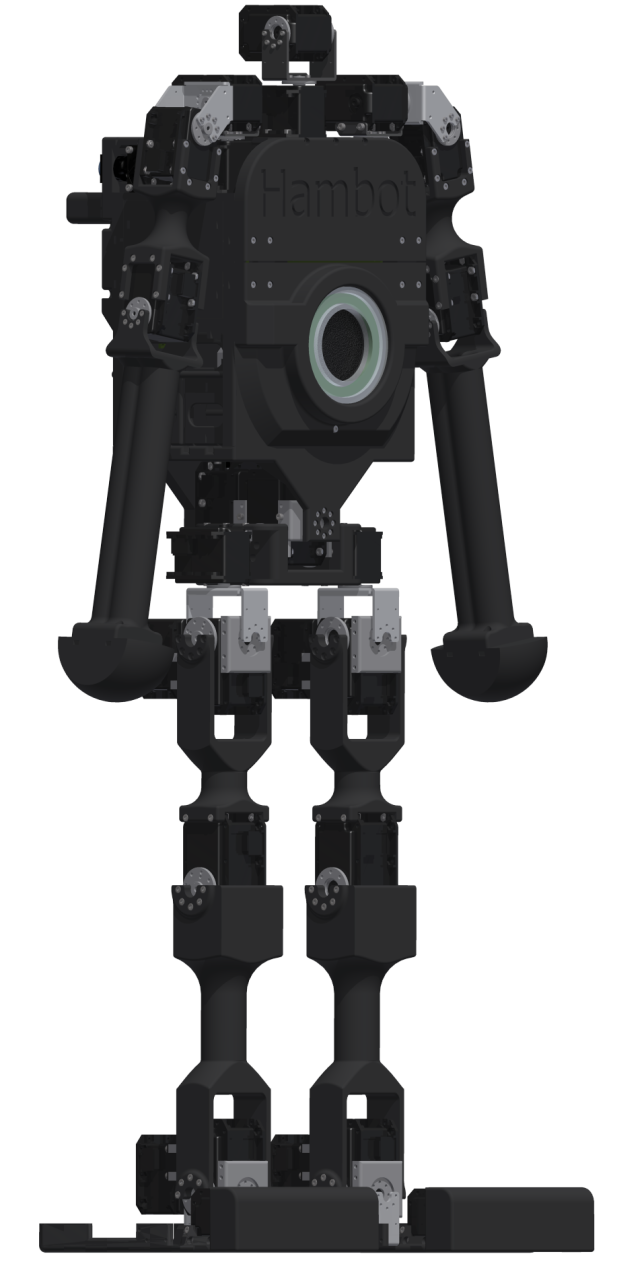

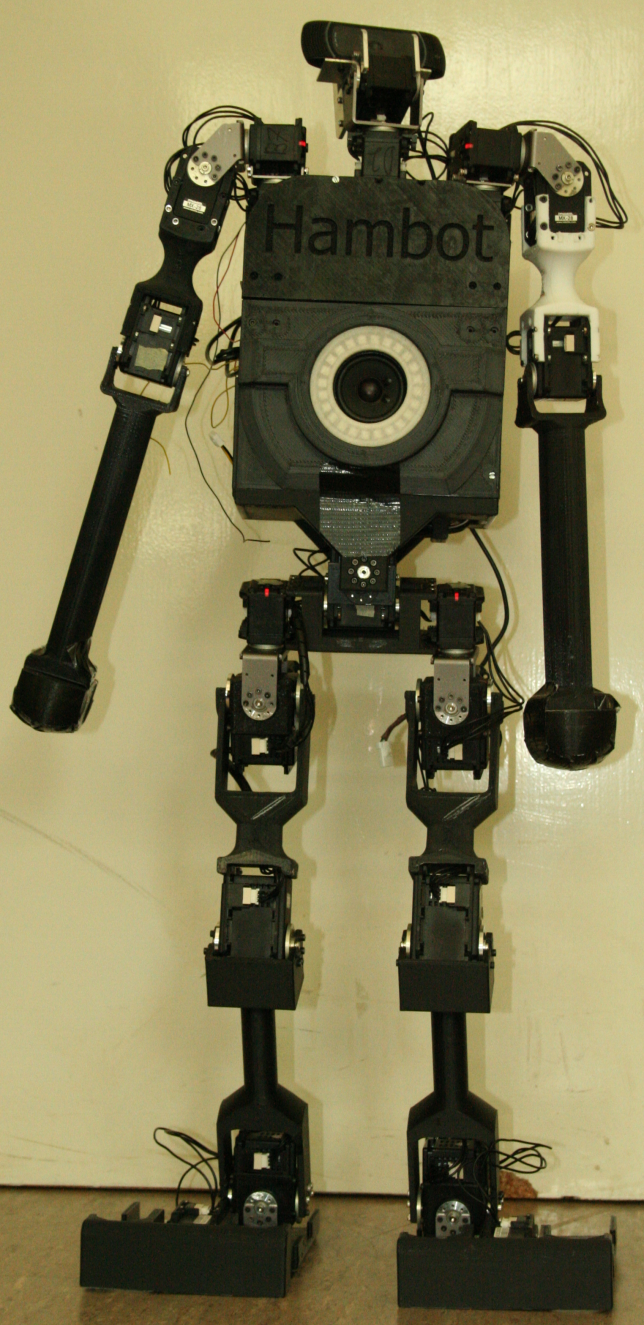

Those of you who read our articles regularly already know that we are again building a new robot. His name is Hambot and he is the second version of GOAL, our robot we took to the world championships in Brazil last year.

Unfortunately GOAL had some problems to get up, because the relations of motor strength and weight were too bad. But during development last year we learned a lot about CAD and mechanics in robotics. Therefore we wanted to build a new version this season — and we did.

The largest change, which can be seen directly, is that Hambot is produced nearly completely by 3D printing. This has many benefits for us, because we can produce our parts directly in the 3D printing lab next to our room. This “Rapid Prototyping” allows us to create several different versions of a part on one day. For the metal parts we had to wait up to several days or even weeks every time. Additionally plastic weights less than aluminum and is cheaper. But the most important advantage are the richer design possibilities. The metal parts could only be arranged in angles of 90 degrees compared to 3D printing, which has nearly no restrictions. This also allows more human-like structures.

The largest change, which can be seen directly, is that Hambot is produced nearly completely by 3D printing. This has many benefits for us, because we can produce our parts directly in the 3D printing lab next to our room. This “Rapid Prototyping” allows us to create several different versions of a part on one day. For the metal parts we had to wait up to several days or even weeks every time. Additionally plastic weights less than aluminum and is cheaper. But the most important advantage are the richer design possibilities. The metal parts could only be arranged in angles of 90 degrees compared to 3D printing, which has nearly no restrictions. This also allows more human-like structures.

These weren’t the only changes we did. We also improved the interaction with the robot a lot. It now has more and illuminated buttons and a LCD touch display on his back. We also added an RGB-LED Ring on the front and a chip for speech synthesis, so we can understand our robot much better than with the previous software-solution.

A very new field for us was the development of the electronics. More details will follow in a later article.

A very new field for us was the development of the electronics. More details will follow in a later article.

Luckily we were able to print the last parts and wire the electronics temporarily last week, because this week Hambot has to show his skills at the IranOpen. We wait eagerly!

Besides our new robot we had another reason to celebrate: Last week we handed in our first paper for the RoboCup symposium. Again more details will follow later.

Conclusively we had an eventful start in the new season. You will find more information about it in the Substanz magazine (a German popular-science magazine), which visited us last week to capture the atmosphere in the lab shortly before a competition.

Both, electronics and models for 3D printing can be found on our Github page, where we will release all our soft- and hardware as open source in future.

https://github.com/bit-bots